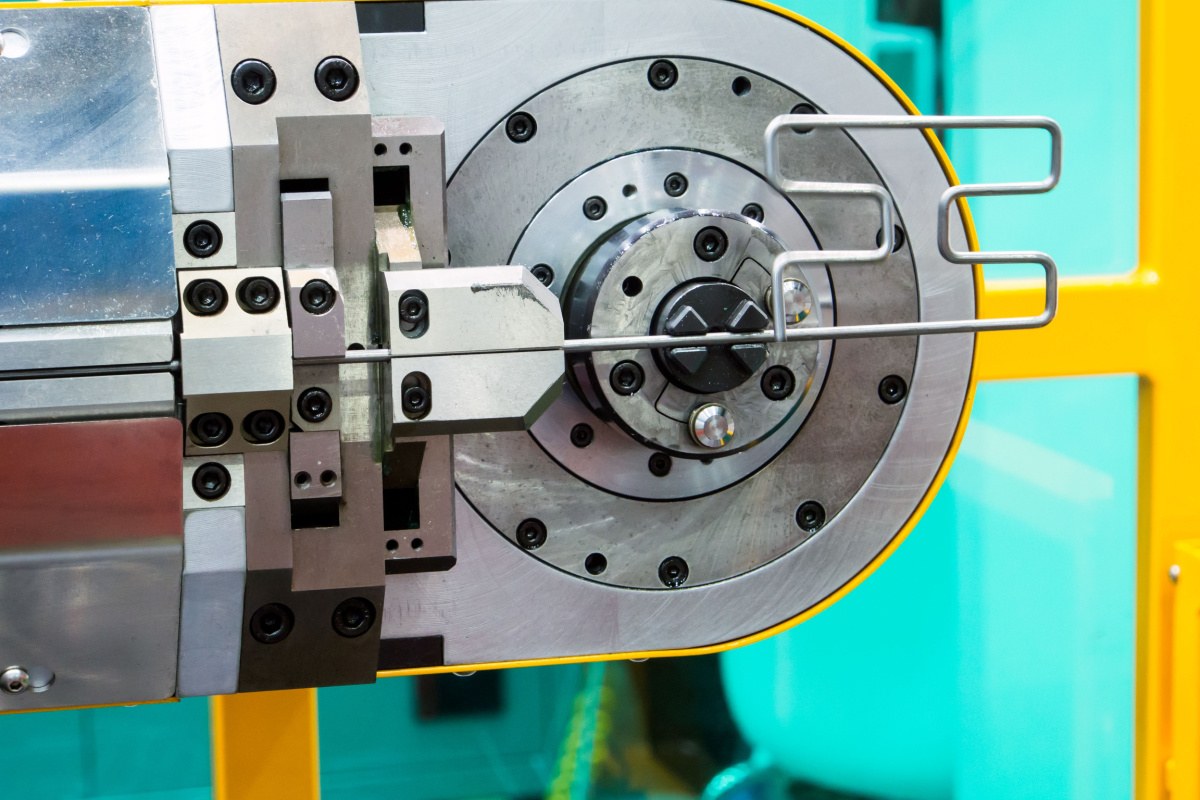

Wire Forming, Wire Shapes and Parts

We’re experts in the assembly, manufacturability and repeatability of wire forms.

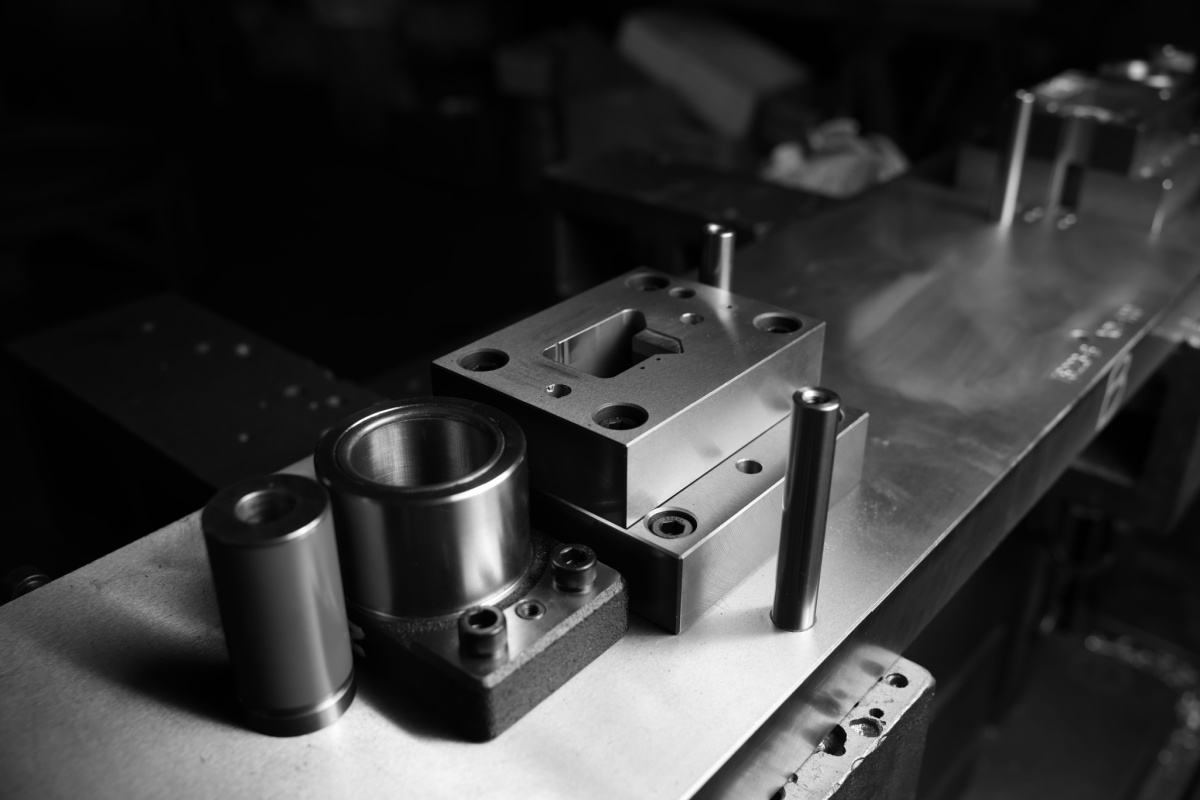

Complex Geometric Components.

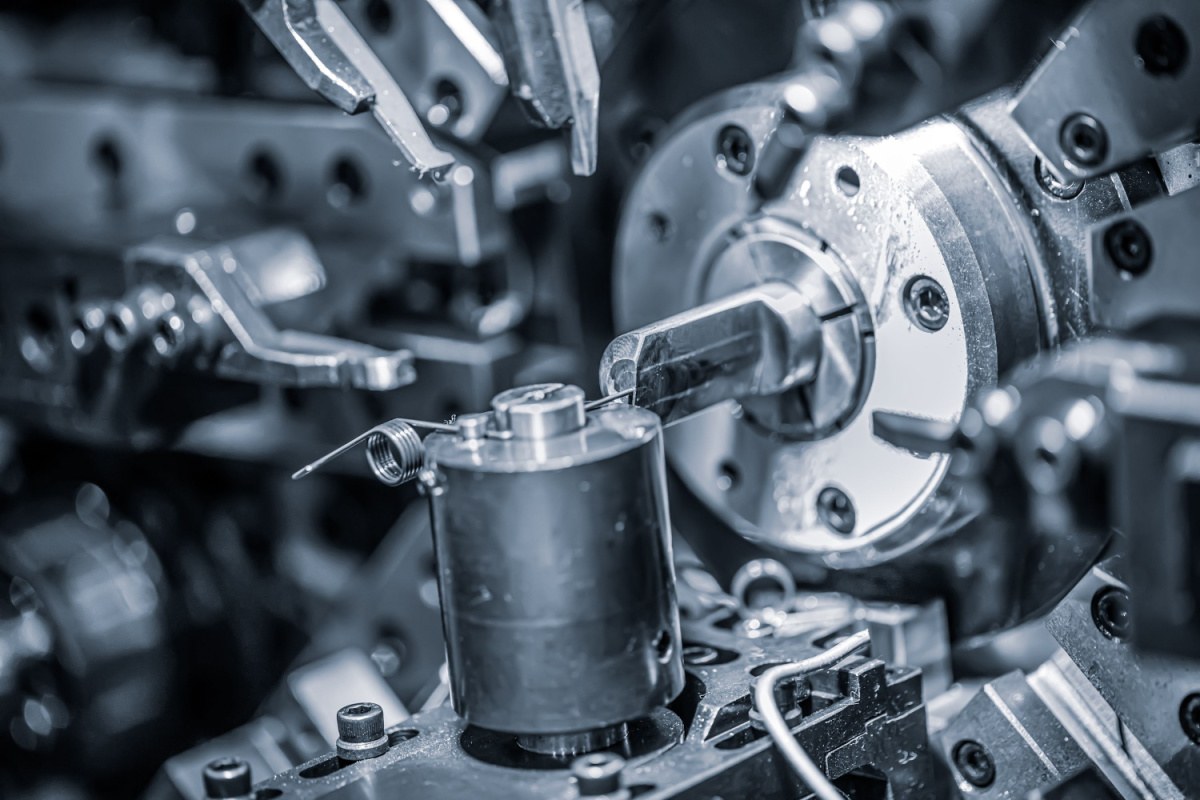

Manufactured using dedicated, medical-grade machines that shape wire to the closest tolerances of any mass manufacturer. They can also be cut, bent and wound in any way.

Precision-Made, Multifunctional.

From simple to highly intricate applications, we create medical wire forms that can be used as isolated components, or integrated with others into a system.

Tight Tolerances, High Performance.

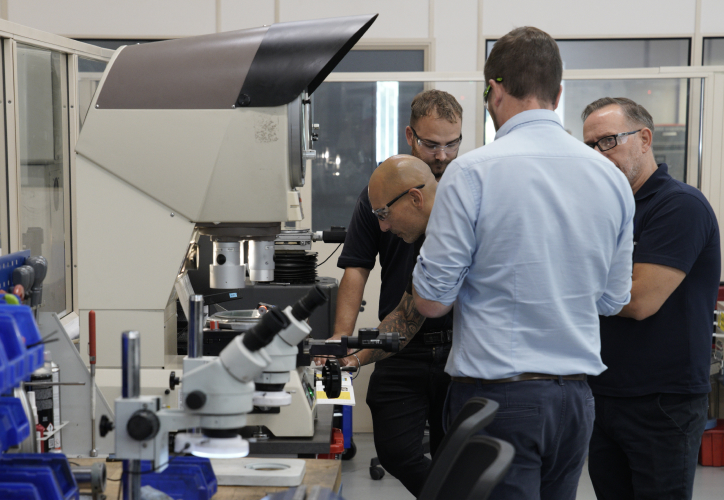

Our in-house experts can support you in producing designs for the performance characteristics you need. We consider the assembly, manufacturability and repeatability in the early stages of the design process.

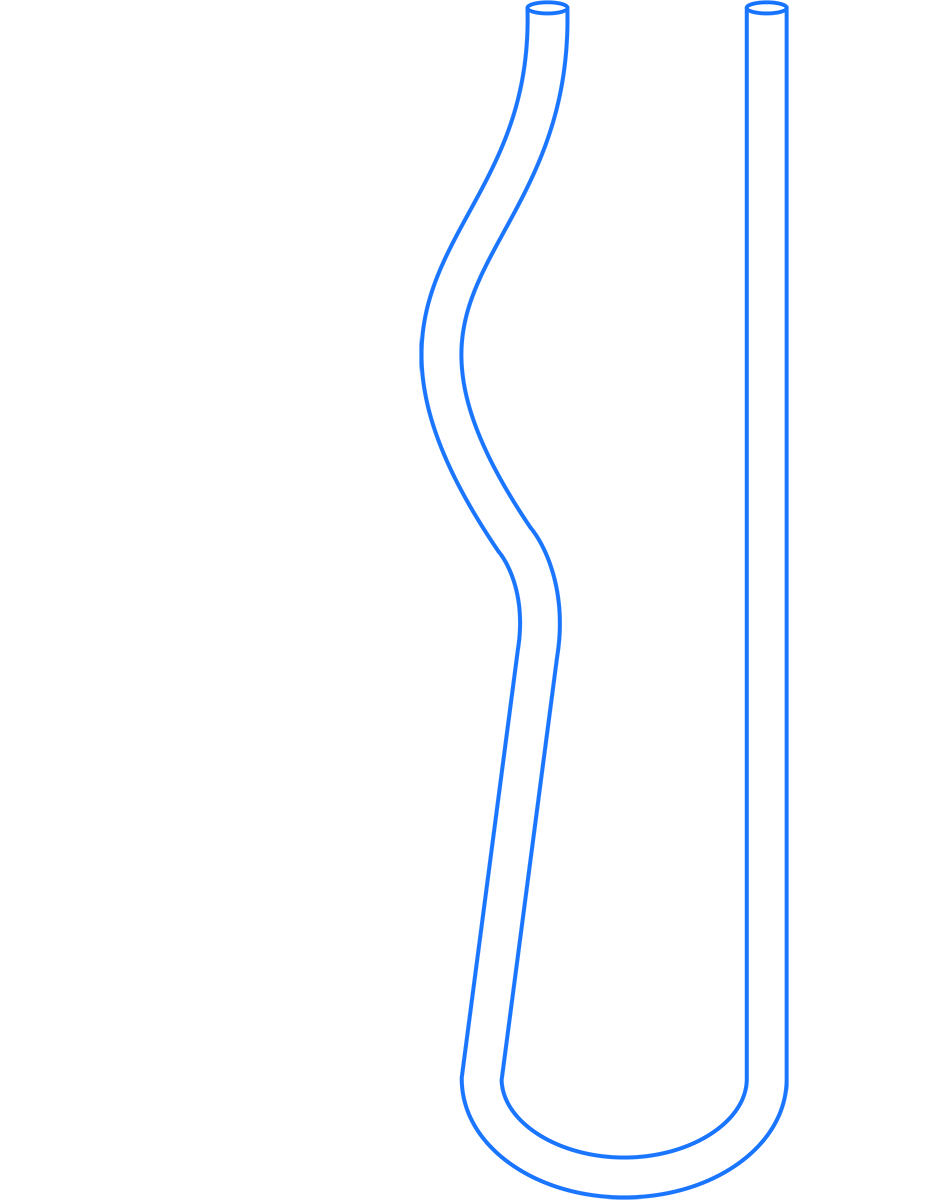

The possibilities of wire forms are potentially even more endless than the springs. A length of wire which has had an exterior force applied to create a specific shape for a specific job, wire forms can be cut, bent, wound, and shaped in infinite ways. This means there is almost no limit to the applications they can be used in.

Advanex Medical creates wire forms, wire shapes and a huge variety of custom wire parts for the medical industry.

Our expert medical engineers are capable of designing solutions for wire as small as 15 microns in diameter, in a wide variety of materials and finishes.

These wire forms are present in all sorts of drug delivery devices and medical applications, with all sorts of functionality, including integrated springs and connections.

Cost Effective Design and Highly Repeatable Production Methods.

Advanex Medical is here to help. We’re experts in producing repeatedly high quality wire forms, shapes and parts for medical manufacturers all over the world. With some of the world’s most advanced mass production equipment, and ISO-7 certified cleanroom facilities, we’re equipped to handle projects of all scopes, complexities and volumes.

Variety, Versatility and Precision Fit For The Industry.

Solutions for every application. We design, prototype, mass produce and continuously improve every product, for every single customer. As proud medical design experts, our teams are situated all over the world to give you local support and lend a hand to solve any and all issues involving production, assembly and quality.

Vast Material Options

Advanex Medical has expertise in manufacturing Spring Steels, Stainless Steels, Copper Alloys, Nickel Alloys, as well as Titanium, Elgilloy, Hastelloy and Kanthal.

Variety of Surface Finishes

We can apply a range of surface finishes to Electroplating, Organic Zinc coatings, Autophoretic painting, Phosphating, Oiling, or as required by our customers.

Applications

We create solutions for all kinds of medical-grade devices, from disposable drug delivery systems to high-tech smart devices, including wearables.

Our experts are here to help.

From design support, to ongoing support for existing customers, we’re here to help you however we can.