Insert Moulding

Advanex Medical are the leaders in insert moulding for pharmaceutical applications. We support manufacturers in creating high-quality wearable and connected technologies, and bring them to the mass market.

Propelling the industry forward.

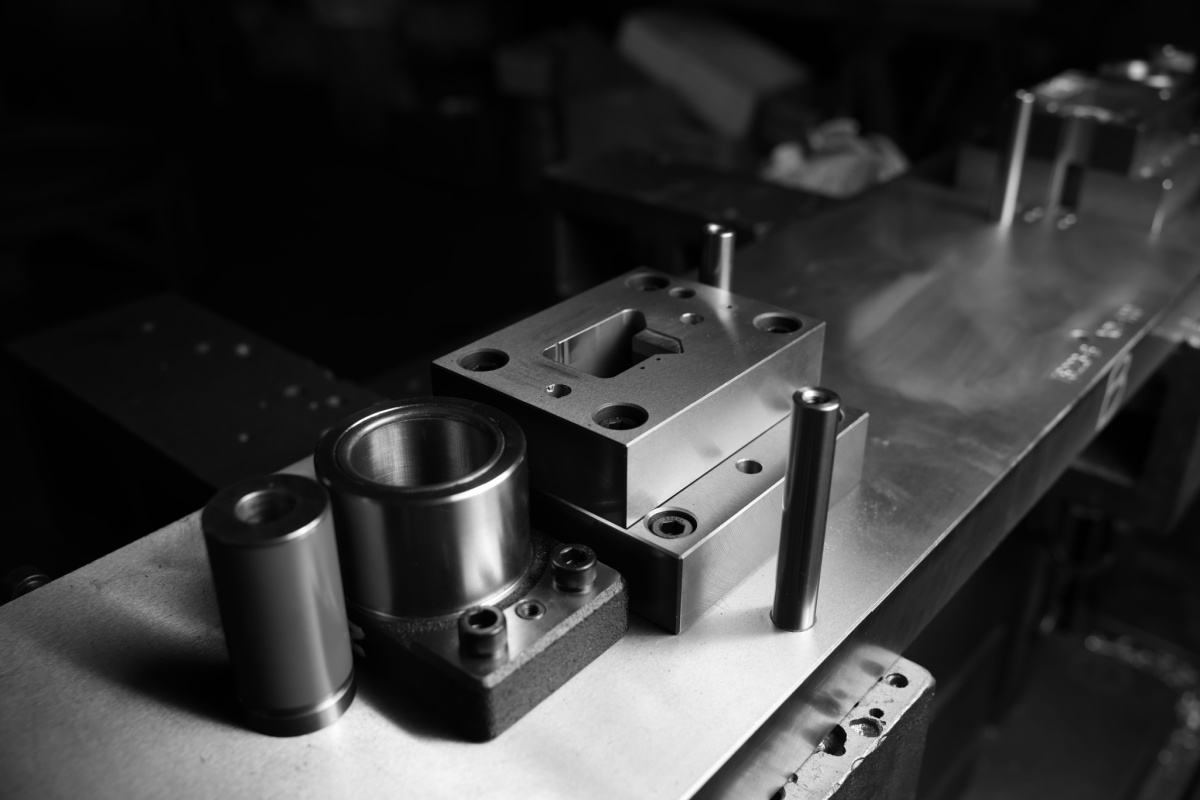

Space-economical, highly reliable and lightweight parts. We produce high precision, quality, ultra-thin components for durability in critical applications.

Custom designed, high precision.

Typically we can produce Insert Moulding components with materials as thin as 0.1 mm. In addition, Insert Moulding technology developed in-house makes stable shape processing achievable, which cannot be replicated by conventional assembly techniques.

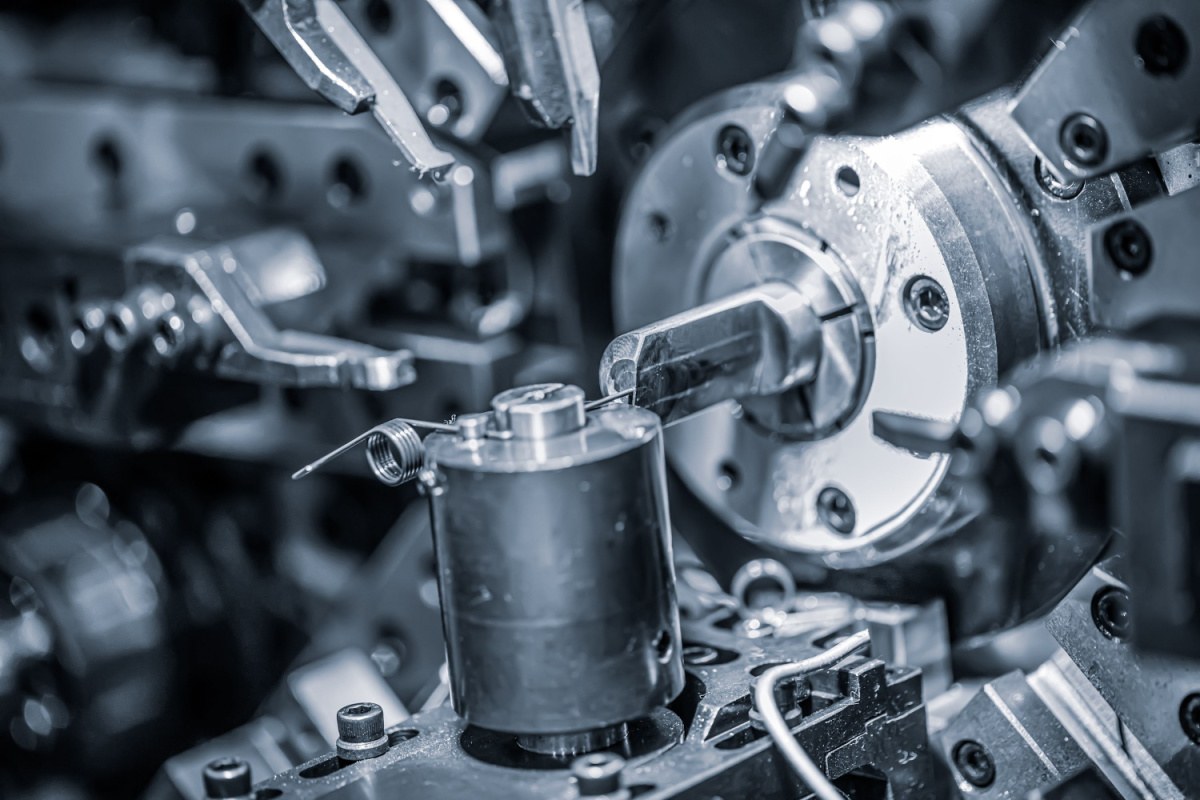

Stamping and insert moulding.

Precision metal and plastic in one unique package. Our single process lowers assembly costs and reduces the number of components required.

High quality insert mouldings, expertly manufactured to bring new medical products to market, faster.

Our streamlined reel-to-reel process coupled with high-precision moulding capabilities allows for quicker production cycles, effectively reducing the time-to-market for your medical devices.

Repeatable manufacture, by design.

Our Insert Moulding seamlessly combines metal and plastic, reducing assembly costs and space requirements. This efficiency streamlines production processes, ensuring manufacturability and repeatability at every manufacturing scale.

Enabling miniaturisation with precise manufacturing.

With expertise in moulding components as thin as 0.1mm, we have an exceptional track record of miniaturisation. With in-house technology for stamping and pressing, combined with automated assembly lines, we are fully equipped to handle compact designs at high volume.

Seamless to assemble

We pioneered the use of reel-to-reel manufacturing techniques. This enables us to provide insert moulded components in a reel, ready to feed into automated assembly lines.

Applications

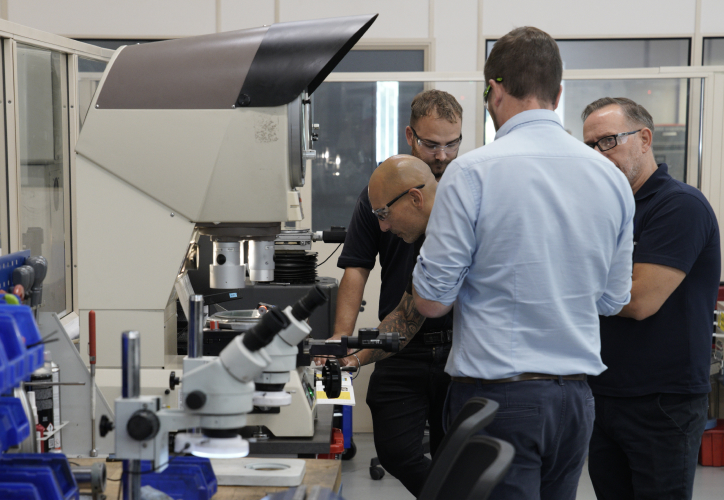

Speak to an insert moulding specialist

Get in touch with an expert at Advanex Medical for dedicated support, design knowledge and much more.