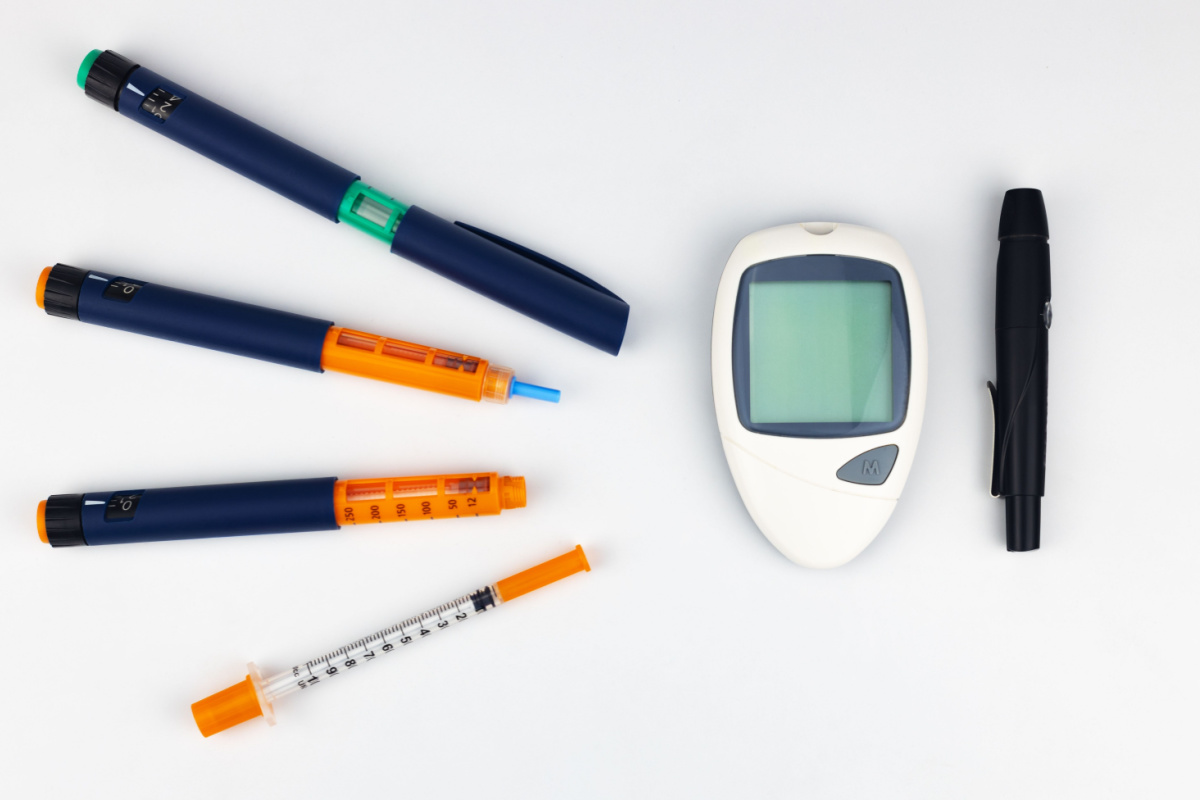

Auto Injector and Drug Delivery System Components

Precision-engineered components for advanced injectable drug delivery systems

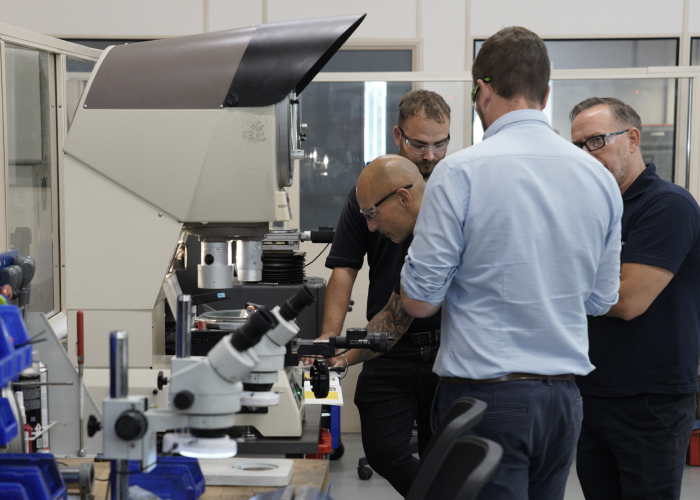

Experts in Auto-Injectors

At Advanex Medical, we manufacture high-performance components for auto injector devices and drug delivery systems for the world’s most trusted medical brands. Our expertly designed springs, stampings and wire forms support safe, effective and reliable medication delivery for self-injection and assisted drug delivery applications.

From insulin injection pens to automatic emergency syringes, our components play a critical role in ensuring that devices deliver exact dosages, meet patient safety standards and offer smooth usability. We support every stage of the device lifecycle from concept to clinical trials, regulatory testing and global mass production.

Applications: Supporting Next-Generation Drug Delivery Devices

Our components are engineered for use across a wide spectrum of modern drug delivery platforms. We supply market-leading mechanical components for the following applications.

These applications rely on components with tight tolerances, validated performance and materials suitable for cleanroom and sterile environments.

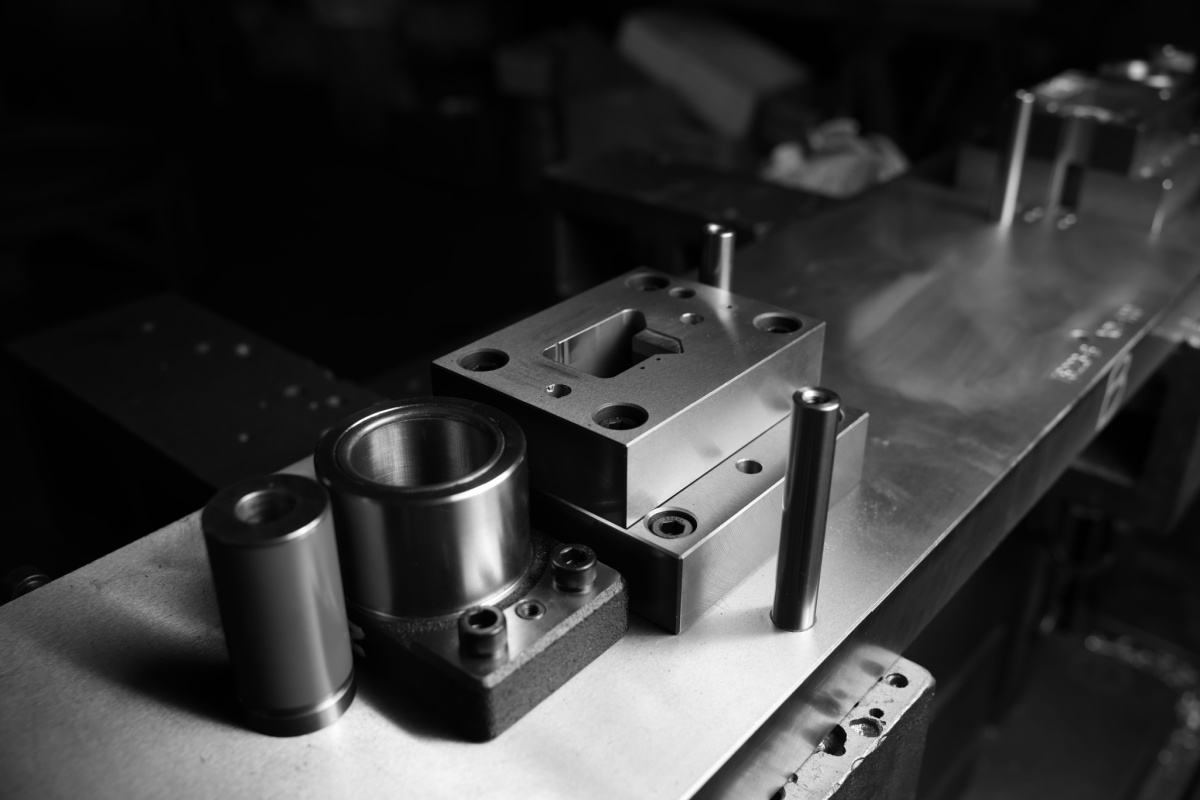

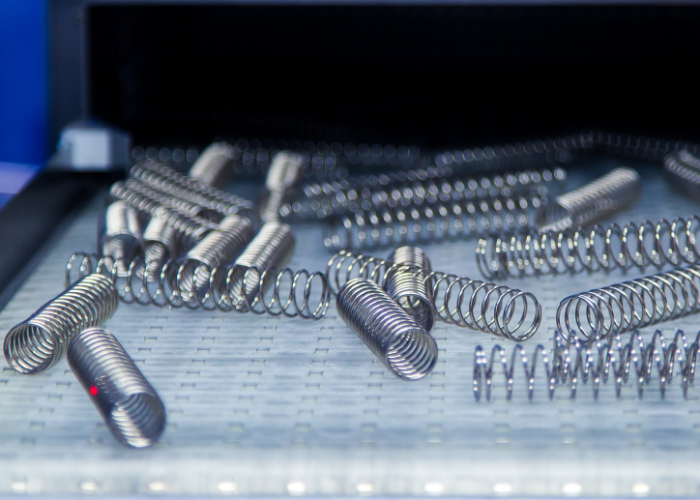

Component Capabilities: Precision Springs and Stampings

Advanex Medical manufacture the essential mechanical parts that drive drug delivery systems:

- Compression springs

- Torsion springs

- Tension springs

- Wave springs

- Power springs

- Constant force springs

- Stampings and deep drawn parts

- Wire forms

We manufacture all auto injector device components using medical-grade materials with full traceability and certification.

Spring Force and Retraction Engineering Expertise

Advanced spring design for performance and safety

We specialise in designing springs that precisely control the delivery force, timing and motion of drug delivery mechanisms. Our in-house team develops components that meet strict fatigue life, load rate and actuation force requirements, ensuring that every device activates predictably and safely.

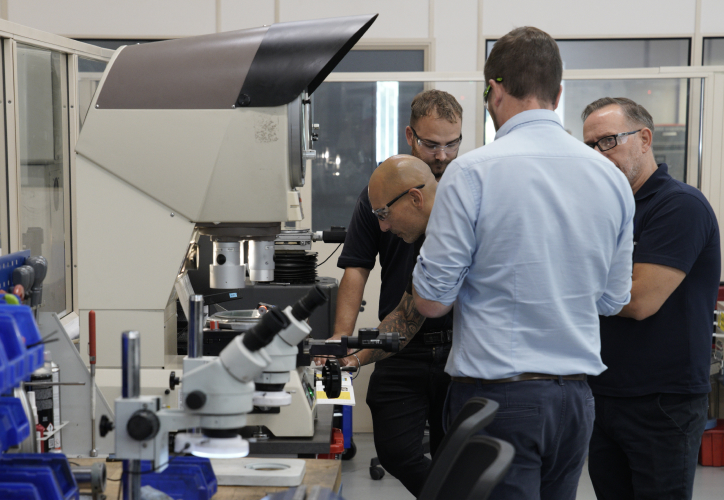

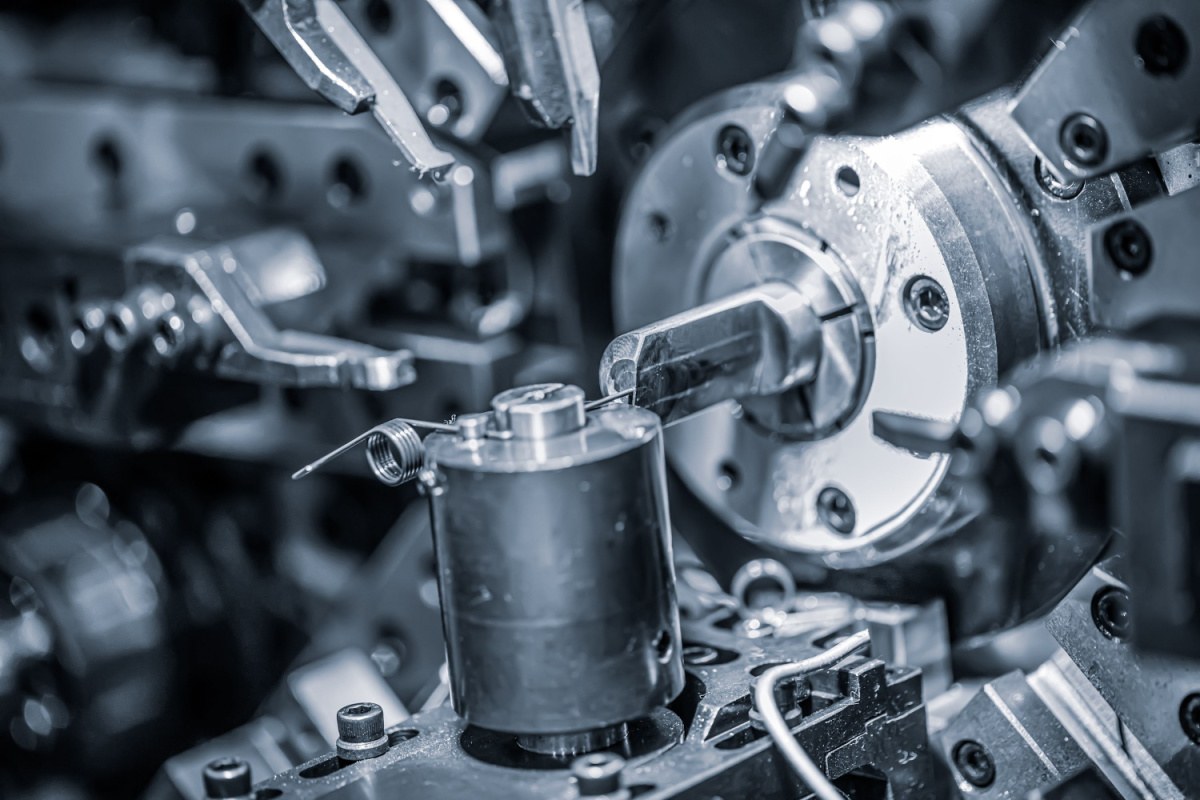

Cleanroom-Ready, Scalable Medical Manufacturing

Automated production and ISO-certified processes

Advanex Medical offers clean, consistent and automated production lines capable of scaling from single prototype runs to millions of parts per year. Our capabilities include:

- Cleanroom manufacturing compatible with sterile medical assemblies

- Automated coiling, forming, stamping and in-line inspection

- Full material and batch traceability

- ISO 13485 certified facilities

- Industry-leading quality control

Our production lines are tailored to the needs of global pharmaceutical and medtech manufacturers.

Comprehensive Project Support from Start to Scale

Engineering-led development and commercialisation

From early concept feasibility to full device commercialisation, our team works closely with yours to ensure every component is production-ready. We support your project as it moves through:

- Early concept stages

- Clinical trials

- Sampling

- Mass production

Whether you’re building your first auto injector or scaling a global launch, we provide solutions that improve quality outcomes, assembly ease and commercial results.

Integrated Component Solutions for Drug Delivery Devices

Metal spring, stamping and formed metal components, all under one roof

Advanex Medical delivers complete solutions for injector devices by combining a wide range of capabilities into a single supplier relationship. Our offering includes:

- Compression, tension, torsion and power springs

- Deep drawn parts and precision stampings

- Formed wire components

With decades of experience in the medical device space, we are uniquely positioned to solve complex engineering challenges with reliable and validated component solutions.

Let’s Build Your Next Drug Delivery System

Need reliable, high-quality drug delivery system components? Looking for custom auto injector device components with global production capability? Talk to Advanex Medical.

Contact us to discuss your project

Auto Injector Devices: Frequently Asked Questions

Typical components include a spring-driven plunger, needle retraction mechanism, drug reservoir and safety lock features. Springs, stampings and formed parts play vital roles in delivering force, triggering actuation and enabling safe re-use prevention.

We use validated design tools and process controls to tightly manage spring load rates and force curves. Our testing includes fatigue, compression and actuation force verification, all under ISO 13485 protocols.

Absolutely. Our engineers collaborate with customers during design and development to optimise the mechanical architecture, material selection and manufacturability of every component.

We use cleanroom-compatible manufacturing, automated handling and strict environmental controls to limit particulates. Processes include filtered air systems, reduced manual contact and clean packaging to ensure component cleanliness.

We design springs with anti-tangle features, such as closed ends or pitch adjustments, and use controlled packaging and orientation systems to keep components separated during production and assembly.